In an era where environmental stewardship intersects with operational excellence, Sustainable Asset Management has emerged as a transformative force in Enterprise Asset Management (EAM). Organizations across the oil and gas, energy, and chemical manufacturing sectors are discovering that integrating green practices into EAM isn’t just a moral obligation—it’s a strategic advantage.

By leveraging cutting-edge technologies like IoT, AI, and predictive analytics, companies are reducing carbon footprints, optimizing resource use, and enhancing asset longevity while driving profitability. This article explores how forward-thinking organizations are redefining asset management through sustainability, offering actionable insights for leaders ready to lead the charge toward a greener future.

The Business Case for Sustainable EAM: Beyond Compliance to Competitive Edge

The global push for sustainability has shifted from regulatory checkbox exercises to a core component of corporate strategy. For asset-intensive industries, this transition is particularly critical. Traditional EAM systems focused on maximizing uptime and minimizing costs, but modern solutions now prioritize environmental, social, and governance (ESG) metrics as equally vital KPIs.

Why Sustainability Matters in Asset Management

- Regulatory Pressures: Stricter environmental regulations, such as carbon taxation and emissions caps, demand proactive compliance. EAM systems equipped with sustainability modules enable real-time tracking of energy consumption, emissions, and waste, ensuring adherence to evolving standards

- Cost Efficiency: Sustainable practices like predictive maintenance and energy optimization reduce operational expenses. For instance, IoT-enabled sensors can cut energy use in industrial facilities by up to 20%, translating to significant savings.

- Brand Reputation: Consumers and investors increasingly favor companies with robust sustainability credentials. A 2024 study revealed that 68% of investors consider ESG performance when making decisions, underscoring the financial upside of green EAM practices.

Companies like Hexagon are pioneering this shift. Hexagon’s HxGN EAM, for example, integrates IoT-driven analytics to monitor equipment health while simultaneously calculating carbon footprints, enabling dual optimization of performance and sustainability

Core Strategies for Green Asset Management

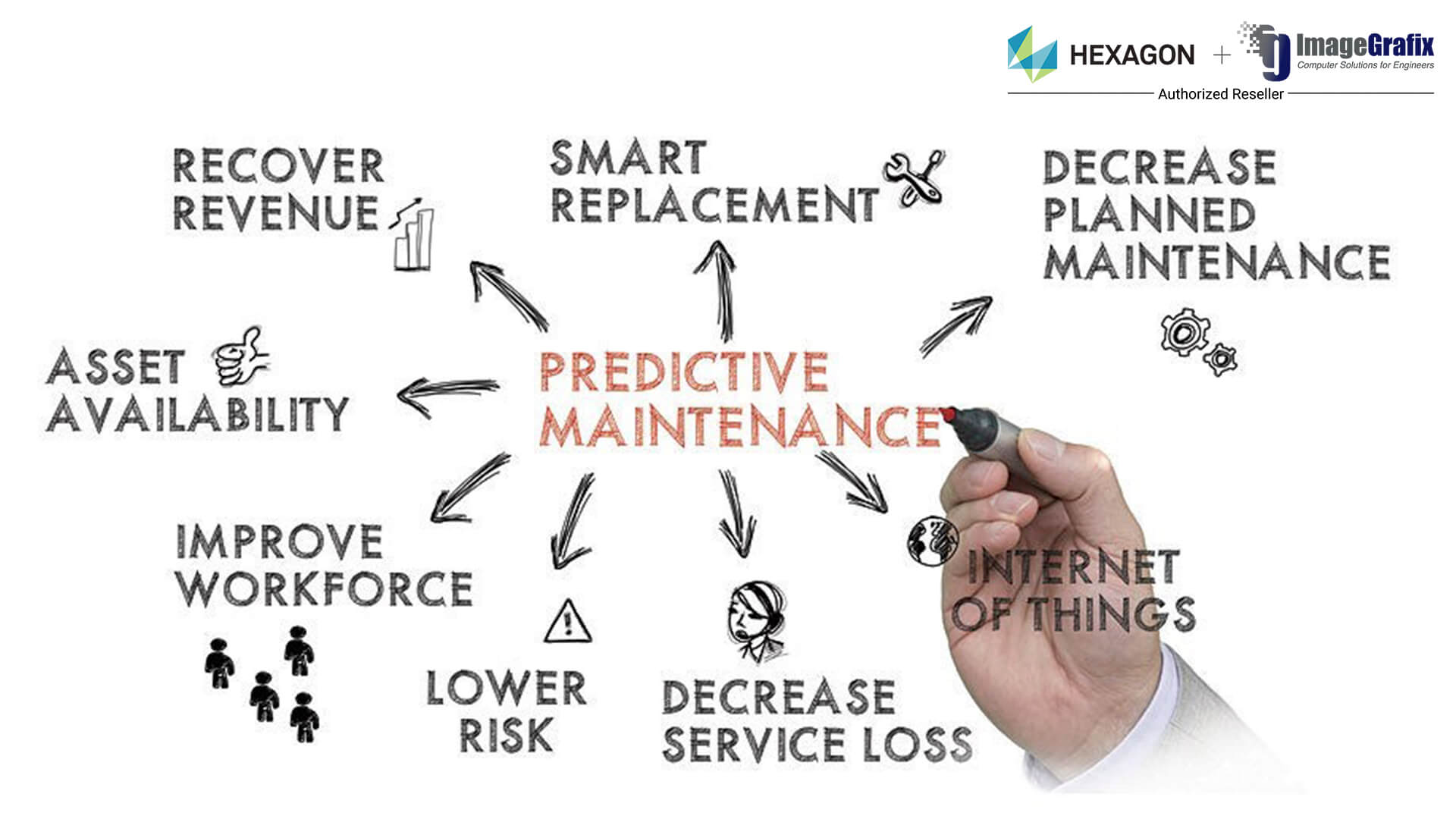

- IoT and Predictive Maintenance: The Backbone of Sustainable Operations – The Internet of Things (IoT) has revolutionized asset management by enabling predictive maintenance. Sensors embedded in machinery collect real-time data on temperature, vibration, and energy use, allowing teams to address issues before failures occur. This proactive approach reduces unplanned downtime by up to 50% and extends asset lifespans, minimizing the need for resource-intensive replacements. In the oil and gas sector, where equipment operates in extreme conditions, IoT-driven EAM systems help companies like Shell and BP monitor pipeline integrity and drilling equipment. By predicting corrosion or mechanical stress, these systems prevent leaks and spills, safeguarding ecosystems while ensuring compliance

- Energy Optimization and Circular Economy Practices – Modern EAM platforms now include modules for tracking energy consumption and promoting circular economy principles. For example:

- Energy Analytics: AI algorithms analyze historical data to identify energy waste patterns. A chemical plant using EAM software reduced its energy use by 18% by optimizing reactor temperatures and compressor cycles.

- Asset Lifecycle Extensions: Reusing and refurbishing equipment components cuts material waste. EAM solution enables companies to track the sustainability credentials of suppliers, ensuring recycled materials are prioritized in procurement.

- ESG Integration: From Reporting to Strategic Alignment – Leading EAM systems now embed ESG metrics directly into dashboards. Hexagon’s HxGN EAM, for instance, allows users to correlate equipment performance with carbon emissions, providing actionable insights for reducing environmental impact. This alignment helps companies meet net-zero targets while maintaining production efficiency.

Digital Innovation: Accelerating the Gren Transition

AI and Digital Twins: Simulating Sustainable Futures

Artificial Intelligence (AI) and digital twin technology are game-changers for sustainable EAM. Digital twins—virtual replicas of physical assets—enable engineers to simulate scenarios and test sustainability strategies without real-world risks.

Blockchain for Transparent Supply Chains

Blockchain technology is gaining traction in EAM for ensuring ethical sourcing and reducing Scope 3 emissions. By creating immutable records of raw material origins, companies like have eliminated conflict minerals from their supply chains, aligning with UN Sustainable Development Goals

Industry-Specific Applications: Oil, Gas, and Chemicals Lead the Way

Oil & Gas: Mitigating Environmental Risks

The oil and gas industry faces unique sustainability challenges, from methane leaks to drilling waste. Advanced EAM solutions address these through:

- Predictive Leak Detection: IoT sensors monitor pipelines in real time, alerting teams to potential leaks before they escalate. A Middle Eastern oil company reduced spill-related costs by $12M annually using this approach

- Flare Gas Recovery: EAM systems optimize flare stack operations, capturing and repurposing methane that would otherwise be burned off. This practice cuts emissions while generating additional revenue

Chemical Manufacturing: Waste Reduction at Scale

Chemical plants are leveraging EAM to minimize hazardous byproducts. Many Companies have implemented a cloud-based EAM system to track solvent use across 30 facilities, reducing toxic waste by 40% through precise inventory management and process adjustments.

Corporate Responsibility: Building Brand Value Through Sustainability

Sustainability isn’t just about compliance—it’s a powerful differentiator. Companies have embedded sustainability into their corporate ethos, achieving a 12% reduction in Scope 1 and 2 emissions through data center consolidation and renewable energy adoption. This initiative, which combines volunteer work with environmental advocacy, has enhanced employee engagement and brand loyalty.

Key Takeaways for Leaders:

- Align EAM with ESG Goals: Use EAM data to demonstrate progress in sustainability reports.

- Engage Stakeholders: Collaborate with suppliers, customers, and employees to create a culture of environmental responsibility.

- Leverage Incentives: Governments worldwide offer tax breaks and grants for green initiatives, offsetting implementation costs.

The Road Ahead: Future Trends in Sustainable EAM

The convergence of AI, IoT, and ESG will drive the next wave of innovation in EAM. Emerging trends include:

- Autonomous Maintenance Systems: AI-driven robots performing repairs in hazardous environments, reducing human risk and emissions.

- Carbon Capture Integration: EAM platforms monitoring carbon sequestration systems in real time.

- Circular Supply Chains: Blockchain-enabled tracking ensuring 100% recyclability of assets.

Companies that adopt these technologies today will lead tomorrow’s markets.

Conclusion:

Pioneering a Greener Tomorrow with EAM

The integration of green practices into EAM represents a seismic shift in how industries manage assets. By prioritizing sustainability, organizations not only mitigate environmental risks but also unlock new avenues for growth and innovation. From predictive maintenance in oil rigs to AI-driven energy optimization in chemical plants, the tools to build a sustainable future are here.

For leaders in the oil and gas, energy, and chemical sectors, the message is clear: Sustainable Asset Management is no longer optional—it’s the cornerstone of resilient, future-ready operations. By partnering with innovators like Hexagon, your organization can transform EAM from a cost center into a catalyst for environmental and economic success.

Ready to embark on your green EAM journey?

The time to act is now—our planet and your profitability depend on it.

Please feel free to contact marketing@imagegrafix.com