AFT Impulse

AFT Impulse is a powerful fluid dynamic simulation tool used to calculate pressure transients in piping systems caused by waterhammer.

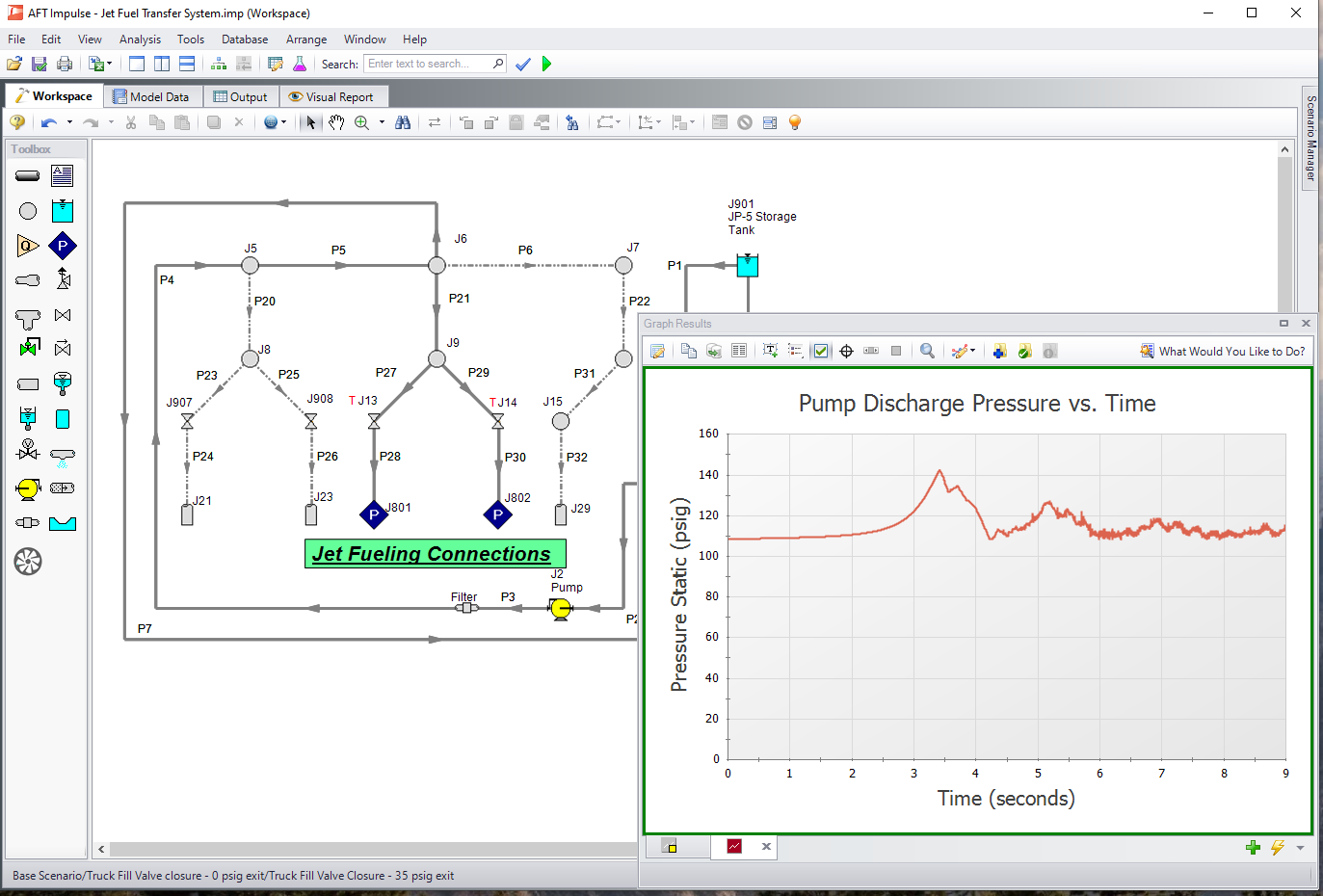

Applied Flow Technology (AFT) Impulse is a powerful fluid dynamic simulation tool used to calculate pressure transients in piping systems caused by waterhammer. Designed for use in liquid systems containing water, petroleum and refined products, chemical products, cryogens, refrigerants, and more, AFT Impulse is an essential tool with the ability to tackle your most demanding systems.

AFT Impulse is particularly useful for:

- Ensuring that pressure extremes are within design allowables.

- Sizing and locating surge suppression equipment.

- Determinig imbalanced pipe forces and sizing structural supports.

- Troubleshooting existing systems to determine the cause of operational problems.

- Evaluating the effect of pressure surges due to vapor cavity collapse.

Features

- Advanced transient solver based on Method of Characteristics.

- Built-in steady-state solver to automatically initialize waterhammer transient.

- Detailed pump inertial modeling for trips and start-ups including state-of-the-art, four quadrant methods.

- Built-in library of fluids and fittings.

- Models liquid column separation caused by transient cavitation.

- Extensive cavitation modeling

- Scenario Manager to track all design variants and operational possibilities in a single model file with data linkage.

- Comprehensive relief valve modeling.

- Integrated graphing and reporting.

- Animation features to dynamically graph transients.

- Create video files from animations to share your results.

- Generates force imbalance files that can be automatically read into CAESAR II ® and TRIFLEX ® pipe stress dynamic models.

- Built-in intelligence to guide you in building better models.

Benefits

- Avoid potentially catastrophic effects of waterhammer and other undesirable system transients.

- Alleviate possible financial and environmental issues associated with inadequate system designs or operational procedures.

- Avoid lost revenue resulting from incidents that cause down time.

- Validate the design of safety features.

- Understand the transient response of your system.

- Know the dynamic interaction of valves, pumps and other components.

Add On Modules

Training by our professional staff helps you learn to make the best use of the software’s wide range of capabilities and modeling techniques. Our seminars review fundamental theory, basic through advanced techniques and hands-on modeling.

- Settling Slurries (SSL) – The only commercial software solution that can model both non-settling and settling slurry waterhammer effects.

- Pulsation Frequency Analysis (PFA) – Helps identify and avoid resonant frequencies in systems, especially in those caused by positive displacement pumps.