In the industrial world, where safety and reliability are paramount, corrosion emerges as a relentless adversary, challenging the integrity, longevity, and operational efficiency of assets. Whether it is the pipelines in oil and gas industries, reinforced concrete structures in civil engineering, or nuclear plant components, the effects of corrosion are profound.

This blog delves into the pervasive impact of corrosion, the latest advancements in its detection and management, and the proactive solutions industries can adopt. It also highlights how ImageGrafix Software Solutions, with its cutting-edge Integrity Management System (IMS), is revolutionizing the way corrosion is tackled in critical sectors.

Corrosion: The Silent Threat to Asset Integrity

Corrosion is far more than material degradation—it compromises structural integrity, jeopardizes safety, and escalates operational costs. Key challenges include:

- Structural Weakness: Pitting corrosion, stress corrosion cracking, and hydrogen embrittlement weaken components.

- Economic Impact: Repair costs, downtime, and production losses weigh heavily on industries.

- Environmental Hazards: Pipeline failures and leaks can lead to environmental disasters.

Understanding Asset Integrity Management (AIM)

Asset Integrity Management (AIM) offers a systematic approach to ensure assets operate efficiently throughout their lifecycle while safeguarding health, safety, and the environment. Key elements include:

- Lifecycle Analysis: Covering design, operation, and maintenance phases.

- Risk-Based Inspection (RBI): Prioritizing inspection efforts based on asset risk profiles.

- Predictive Maintenance: Leveraging advanced tools and analytics to foresee failures.

Advancements in Corrosion Detection and Management

- Novel Detection Methods

- Non-Destructive Testing (NDT): Techniques like acoustic emission testing and phased-array ultrasonics provide real-time corrosion detection.

- Electrochemical Impedance Spectroscopy (EIS): Aids in identifying early-stage corrosion and evaluating coating performance.

- Advanced Modelling Tools

- Pitting Corrosion Analysis: Computational tools predict pitting behavior in metals, facilitating better material selection.

- Stress Corrosion Cracking in Nuclear Plants: Models assess crack propagation, enabling proactive interventions.

- Digital Transformation

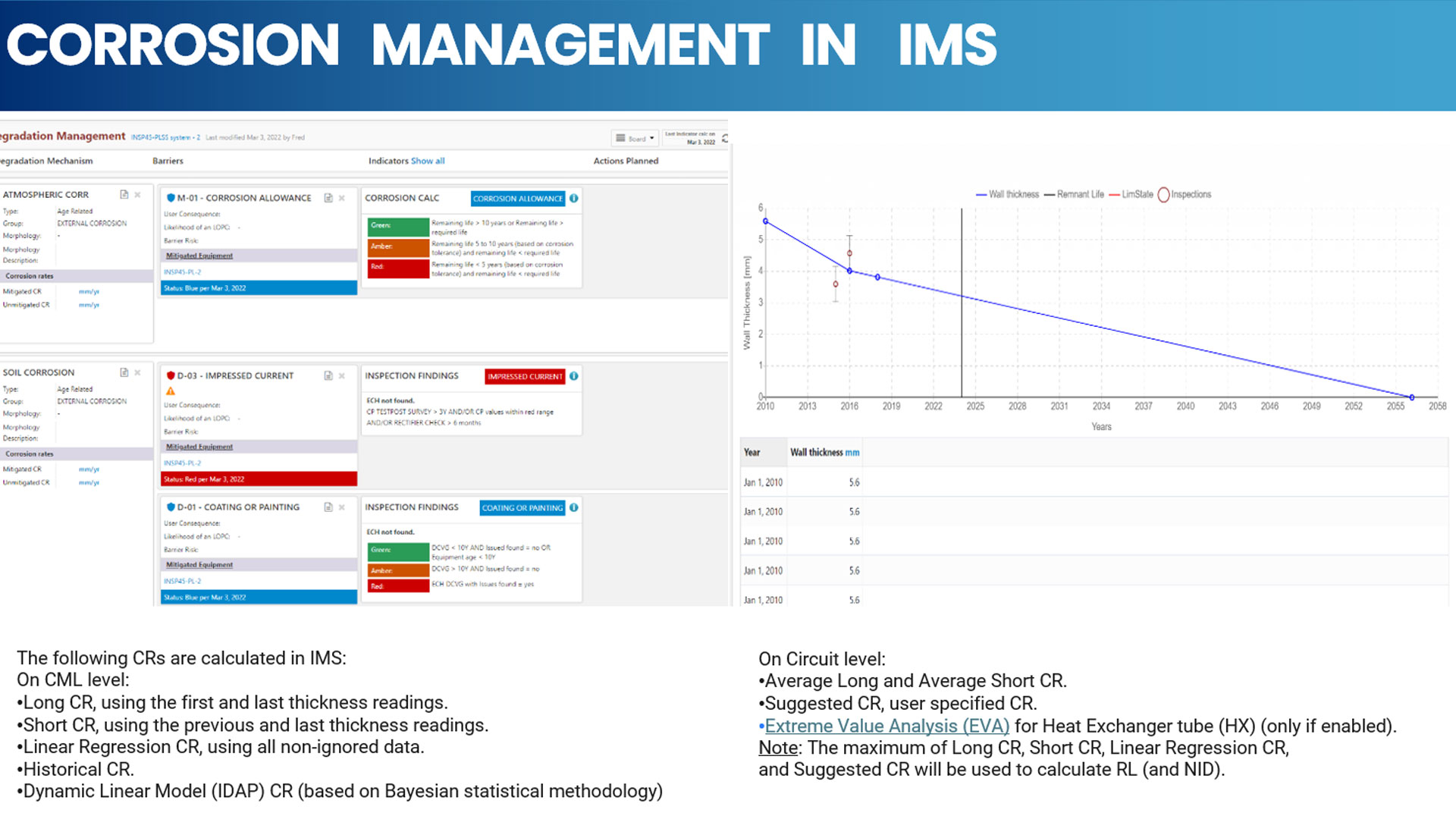

- Integrity Management Systems (IMS): Platforms like Cenosco IMS integrate 2D/3D visualization, mobile accessibility, and predictive analytics to monitor and manage corrosion comprehensively.

Applications Across Industries

Refineries

- Challenges: Sulfur-rich hydrocarbons accelerate corrosion in pressure vessels and pipelines.

- Solutions: Cenosco IMS integrates Fitness-for-Service (FFS) Level-3 analysis and Remaining Life Assessments (RLA) to prioritize maintenance.

Power Plants

- Hydrogen Infrastructure: Materials optimized for hydrogen permeation resistance ensure longevity in high-pressure environments.

- Mitigation Strategies: Corrosion inhibitors and IoT-enabled devices enhance system integrity.

Oil and Gas Pipelines

- Internal Corrosion: Advanced chemical inhibitors and pigging technologies maintain structural reliability.

- Predictive Analytics: Data-driven tools forecast risks and schedule timely repairs.

Reinforced Concrete Structures

- Corrosion in Steel Reinforcement: Chloride ingress and carbonation accelerate degradation. Advanced coatings and inhibitors protect structural elements.

How ImageGrafix Software Solutions Leads the Way

ImageGrafix Software Solutions, in collaboration with Cenosco, offers industry-leading tools to tackle corrosion challenges. Their Integrity Management System (IMS) is a game-changer for asset integrity. Key features include:

- Predictive Maintenance: Shift from reactive to predictive strategies, reducing unplanned downtime.

- Comprehensive Inspection Management: Track inspections, leaks, and repairs with robust data management.

- Advanced Visualization: Real-time 2D and 3D asset health models aid informed decision-making.

- Automated Reporting: Streamlined processes enhance accuracy and efficiency.

- Mobile Solutions: Engineers can access critical data anytime, anywhere.

Future Perspectives: A Holistic Approach to Corrosion

- Innovation in Materials

- Next-generation alloys and composites for extreme environments.

- Sustainable coatings and inhibitors to align with environmental goals.

- Digital Twins

- Real-time simulations of assets for better prediction and response.

- Industry Collaboration

- Partnerships across industries to share insights and drive innovation.

Conclusion

Corrosion is an inevitable challenge, but it is one that can be effectively managed with the right tools, technologies, and strategies. By integrating solutions like Cenosco IMS and embracing predictive analytics, industries can not only protect their assets but also enhance operational efficiency and ensure safety.

ImageGrafix Software Solutions is at the forefront of this revolution, offering advanced solutions that empower industries to tackle corrosion with confidence and precision. By prioritizing innovation, sustainability, and proactive measures, the future of asset integrity management is secure.

Discover how ImageGrafix can transform your asset management practices and turn the tide against corrosion. Visit ImageGrafix Software Solutions to learn more.

For a deeper understanding of how ImageGrafix and Cenosco are revolutionizing asset integrity management, you may find the following resource insightful:

https://www.youtube.com/watch?v=8aa0UkNUtt8&t=8s

Author of this article is Mr. Sameer Patkar, Practice Head – EAM, AIM, Advanced Analytics and IOT.

Sameer is reachable at Sameer.patkar@imagegrafix.com